In modern electronics, two terms frequently encountered are PWB (Printed Wiring Board) and PCB (Printed Circuit Board). PWB is foundational elements in electronic devices, providing pathways for electrical connections. They are the skeletal framework onto which components are later added. While PCB represents a more advanced stage in circuit board technology. Though the terms PWB and PCB are often used interchangeably, they have a few differences in their design, manufacturing process, and applications.

This article aims to demystify these two critical components of modern electronics. By exploring their differences, applications, and significance, we provide a clear understanding that is essential for anyone involved in electronic design and manufacturing.

A Printed Wiring Board (PWB) is a fundamental component in the field of electronics, serving as the backbone for various electronic devices. Essentially, a PWB is a board that facilitates the connection of different electronic components through a network of conductive pathways. These pathways, often made of copper, are etched or printed onto a non-conductive substrate, which is typically a rigid or flexible insulating material.

The primary role of a PWB is to provide a physical platform for the layout of electrical connections. It does not come with pre-mounted electronic components; instead, it offers the necessary structure for these components to be added later. This characteristic distinguishes PWBs from their more complex counterparts, Printed Circuit Boards, which already have electronic components attached.

The material composition and structure of a Printed Wiring Board are pivotal in its functionality and performance. A PWB primarily comprises two essential components: the substrate and the conductive pathways.

The substrate, which forms the base of a PWB, is made from non-conductive materials. Commonly used substrates include fiberglass, phenolic resin, and various types of plastics. Fiberglass, especially in the form of FR-4, is widely favored for its durability and effective insulation properties. Phenolic resin, another popular choice, offers cost-effectiveness and sufficient insulation for less demanding applications. These materials provide the necessary mechanical support and electrical insulation for the conductive pathways.

On top of the substrate lies the network of conductive pathways. These are thin lines of conductive material, usually copper, which are either etched or printed onto the substrate. The copper pathways are crucial as they define the route through which electrical currents flow within the electronic device. Their thickness and layout are carefully designed to meet the specific electrical requirements of the device.

Thermal management is a critical aspect of Printed Wiring Boards, especially as electronic devices become more compact and powerful. Efficient heat dissipation is essential to ensure the longevity and reliability of electronic components mounted on a PWB.

The primary challenge in PWB thermal management is to effectively remove the heat generated by electronic components during operation. If not managed properly, this heat can lead to component failure, reduced performance, and even damage to the PWB itself. To address this, several strategies are employed in the design and construction of PWBs.

Use of thermal vias: Thermal vias create a path for heat to move away from hot components and dissipate more effectively. This is particularly useful in multilayer PWBs, where heat needs to be transferred across different layers.

Substrate materials with good thermal properties: Materials like FR-4 are commonly used because they provide a balance between electrical insulation and thermal conductivity. In some high-performance applications, substrates with even better thermal performance, such as ceramic or metal-core boards, might be used.

The manufacturing process of Printed Wiring Boards is a meticulous procedure that involves several key steps, each critical to the board's functionality and quality. Understanding this process is essential for anyone involved in electronics design and manufacturing.

Design and Layout: The process begins with the design phase, where engineers use specialized software to create a blueprint of the PWB. This design includes the layout of conductive tracks, pads for component placement, and any holes or vias needed. The precision in this stage is crucial as it determines how well the components will fit and function on the board.

Preparing the Substrate: The substrate, typically made of materials like fiberglass or phenolic resin, is prepared to form the base of the PWB. It is cut to the required size and cleaned to ensure there are no contaminants that might affect the adhesion of the conductive material.

Applying the Conductive Material: Copper is the most commonly used conductive material for PWBs. In this step, a thin layer of copper is applied to the substrate. This can be done through various methods, such as laminating a copper foil onto the substrate or coating it with a thin layer of copper through electroplating.

Pattern Transfer: The next step is to transfer the circuit pattern onto the copper layer. This is typically done using a light-sensitive material called photoresist. The photoresist is applied to the copper, and then the board is exposed to light through a mask that has the circuit pattern. The areas of the photoresist exposed to light harden, while the unexposed areas remain soft.

Etching: The board is then subjected to an etching process, where a chemical solution is used to remove the unprotected copper (the areas where the photoresist was soft). This leaves behind the copper in the shape of the circuit pattern.

Drilling and Plating: If the design requires, holes or vias are drilled into the board. These are then plated with copper to establish connections between different layers of the board or to provide mounting points for components.

Finishing: Finally, the board may receive a protective coating to prevent oxidation of the copper and to insulate the tracks from accidental contact. This coating, often a solder mask, also gives the board its characteristic appearance.

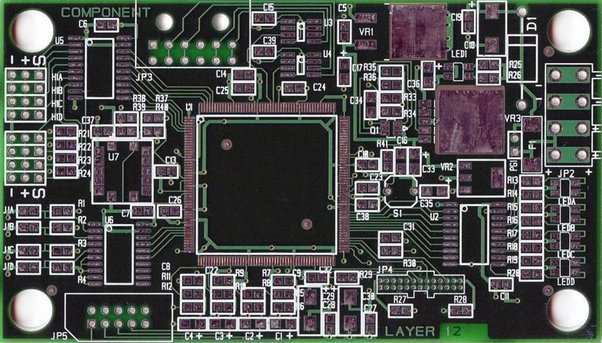

PCB is an advanced type of circuitry used in various electronic devices. It is a step beyond the Printed Wiring Board (PWB) in complexity and functionality. Essentially, a PCB is a board that not only provides pathways for electrical connections, like a PWB, but also has electronic components such as resistors, capacitors, and integrated circuits mounted directly onto it.

The structure of a PCB is composed of multiple layers, including a substrate (usually made of a material like fiberglass), a conductive copper layer, and a solder mask. The substrate provides the base and mechanical support, while the copper layer forms the circuitry with etched lines that create pathways for electrical signals. The solder mask, typically green, covers the board and helps prevent short circuits by insulating the copper traces.

PCBs can be single-sided, double-sided, or multilayered, depending on the complexity required. In a single-sided PCB, the circuit is only on one side of the substrate. A double-sided PCB has circuits on both sides, and a multilayered PCB contains several layers of circuitry stacked together, allowing for more complex and dense designs.

The material composition and structure of a Printed Circuit Board are integral to its functionality and performance in electronic devices. A PCB typically consists of multiple layers, each serving a specific purpose.

Substrate: The foundation of a PCB is the substrate, usually made from a material called FR-4, which is a kind of fiberglass. This material is chosen for its durability and its ability to provide a stable, insulating base for the conductive layers. In some high-performance PCBs, more advanced materials like polyimide or PTFE (Teflon) are used for better heat resistance and electrical properties.

Conductive Layers: On top of the substrate are the conductive layers, primarily made of copper. These layers form the circuitry of the PCB, with copper tracks etched into them to create pathways for electrical signals. The thickness of these copper layers can vary, depending on the current-carrying requirement of the PCB. In a multilayer PCB, several layers of these copper circuits are stacked and separated by insulating material.

Solder Mask: The next layer is the solder mask, which is usually green but can come in other colors. This layer covers the entire PCB, except for the areas where components will be soldered. The solder mask serves an important role in preventing short circuits by insulating the copper tracks.

Silkscreen: The final layer is the silkscreen, which is applied on top of the solder mask. This layer typically contains printed text and symbols that provide information about the component locations, part numbers, and other important details for assembling and testing the PCB.

Thermal management in Printed Circuit Boards is a crucial aspect of their design and functionality. As electronic devices become more advanced, they generate more heat, which needs to be effectively managed to ensure the longevity and reliability of the PCB and its components.

Complexity and Component Density: PCBs often have higher component density and complexity. This leads to more heat generation, necessitating advanced thermal management solutions.

Use of Thermal Vias: PCBs commonly use thermal vias to transfer heat from one layer to another or to the opposite side of the board. These vias are filled with a thermally conductive material, usually copper, to enhance heat dissipation.

Heat Sinks and Cooling Techniques: In PCBs, especially those in high-power or high-speed applications, additional cooling techniques such as heat sinks, cooling fans, or even liquid cooling systems are employed.

Material Selection: PCBs may use materials with higher thermal conductivity, like aluminum or copper substrates, for better heat dissipation, especially in LED lighting systems or high-frequency applications.

Design Considerations: The layout of a PCB, including the placement of components and routing of traces, is often optimized for heat dissipation. Components that generate more heat are strategically placed to minimize thermal stress on sensitive parts. Learn more about design practices that ensure better thermal management.

PCB manufacturing is a more complex process involving multiple layers, intricate etching, advanced drilling for vias, and sophisticated component mounting and testing.

Design and Layout Complexity: PCBs often have complex multi-layer designs. The process starts with detailed design software to layout circuits, component placement, and vias. This design is more intricate due to the need to accommodate multiple layers and various components.

Layering and Lamination: In multilayer PCBs, several layers of material, including conductive copper and insulating substrates, are stacked and laminated together under heat and pressure. This step is crucial for multilayer PCBs to ensure signal integrity and mechanical strength.

Advanced Etching Processes: PCBs use sophisticated etching techniques to create precise circuit patterns on each layer. This often involves more complex chemical processes to handle multiple layers and finer traces.

Drilling and Plating Vias: PCBs require precise drilling for vias, which are then plated with copper to create electrical connections between layers. This step is more advanced in PCBs, especially when dealing with blind or buried vias.

Component Mounting and Soldering: PCBs undergo surface mount technology (SMT) or through-hole technology for component placement and soldering. This includes automated processes for placing and soldering components onto the board.

Testing and Quality Assurance: Given their complexity, PCBs undergo rigorous testing, including electrical tests to ensure connectivity and functionality of all circuits and components.

| Aspect | PWB (Printed Wiring Board) | PCB (Printed Circuit Board) |

|---|---|---|

| Definition | A board that provides the pathways for electrical connections. | A board that not only provides pathways but also has electronic components attached to it. |

| Complexity | Generally simpler, often single-layered. | More complex, can be single, double-sided, or multilayer. |

| Components | Does not come with pre-mounted electronic components. | Comes with electronic components like resistors, capacitors, integrated circuits, etc. |

| Usage | Used in simpler electronic devices where basic connectivity is required. | Used in more complex devices requiring intricate circuitry and multiple connections. |

| Manufacturing | Simpler manufacturing process; involves basic etching and minimal drilling. | More complex manufacturing; involves advanced etching, drilling, and multilayer lamination. |

| Design | Focuses on creating conductive pathways on the substrate. | Involves detailed layout for circuit paths, component placement, and vias. |

| Thermal Management | Less concern for thermal management due to lower component density and heat generation. | Requires advanced thermal management solutions due to higher heat generation. |

| Cost | Generally less expensive due to simpler design and manufacturing. | More expensive due to complexity in design and manufacturing processes. |

| Applications | Suitable for less complex applications like power supplies, basic consumer electronics. | Used in complex applications like computers, smartphones, medical devices, aerospace tech. |

These differences highlight the distinct roles and applications of PWBs and PCBs in the electronics industry, with PCBs being the more advanced and feature-rich option suitable for complex electronic devices.

Besides PCB and PWB, you may still want to know about PCBA, CCA, PCA, and PWA. These terms are also used for printed circuit boards.

This term refers to a PCB that has been fully equipped with its electronic components. The process of PCBA involves soldering components onto the PCB, which can include resistors, capacitors, transistors, and other elements necessary for the board's functionality. PCBA is a critical step in transforming a bare PCB into a fully functional component ready for use in electronic devices.

Similar to PCBA, CCA refers to the assembly of electronic components onto a circuit card, which is another term for a PCB. CCA is often used in contexts where the board is more card-like, typically in computer hardware and other digital devices. The term emphasizes the assembly aspect of the process, highlighting the integration of various components onto the base board.

PCA is essentially synonymous with PCBA and CCA. It denotes the complete assembly of a printed circuit, including the board and all its electronic components. The term is less commonly used but still recognized in the electronics manufacturing industry.

PWA is similar to the above terms but is more commonly associated with PWBs. It refers to a PWB that has been assembled with all necessary wiring and components. While the term is less prevalent, it is still used in certain sectors of the industry, particularly in contexts where the focus is on the wiring aspect of the board.

In conclusion, understanding the distinctions between Printed Wiring Boards (PWB) and Printed Circuit Boards (PCB) is essential in the field of electronics. While PWBs provide the foundational layout for electrical connections, PCBs take a step further by integrating electronic components onto the board. The complexity, manufacturing processes, and applications of these two types of boards vary significantly, with PCBs being more advanced and suited for complex electronic devices.

Recognizing the differences and applications of PWB and PCB is not just a matter of technical understanding but also a key to innovation and advancement in electronics. As technology continues to evolve, the roles and functionalities of PWB and PCB are likely to expand, driving further developments in this dynamic field.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us