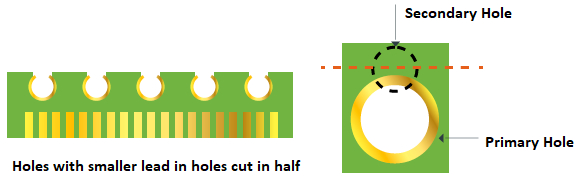

Castellation pcb is also known as castellated hole pcb or plated half holes pcb, which rows of holes are routed on the edges of the pcb and only a half of each plated hole remains in the PCB. PCBs with castellated holes are used to solder one PCB directly to another PCB or insert special design edge connectors.

Castellated holes pcbs are becoming more important especially with the rapid development of high-tech industry. Plated half-holes are mainly used board-on-board connections and can be applied in many applications.