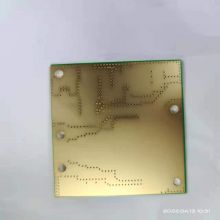

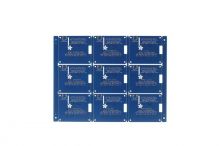

FR4 PCBs are printed circuit boards made with FR4 material that is one of the most popular materials used in the PCB fabrication and assembly. FR4 PCB is a printed circuit board that essentially uses the FR4 sheets and widely used for many applications..