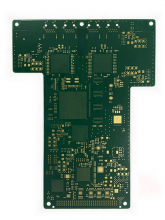

High Density Interconnect, or HDI, circuit boards are printed circuit boards with a higher wiring density per unit area than traditional printed circuit boards (PCB). In general, HDI PCBs are defined as PCBs with one or all of the following: microtraces, VIP (Via In Pad), microvias, blind vias, buried vias or other microvia technique, built-up laminations and high signal performance considerations.