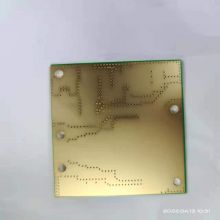

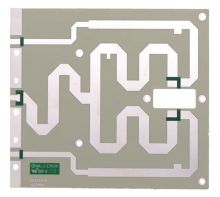

Rogers PCB is a high frequency printed circuit board created from Rogers Company's material, which manufactures the laminate materials for manufacture electronic circuit boards. Rogers is different from another PCB material: FR-4 (Flame Retardant level 4) material, a composite of glass fiber/epoxy, with copper foil laminated on one or both sides. While rogers has no glass fiber in the middle and uses a ceramic base as the high-frequency material. Rogers PCBs, as opposed to FR-4 PCBs are well suited for high-frequency applications.