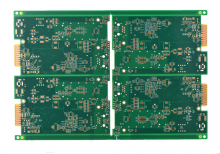

Enig refers to Electroless Nickel Immersion Gold, is a type of surface plating used for printed circuit boards. ENIG PCBs (also named ENIG PC boards or ENIG circuit board Construction) consists of an underlying layer of nickel with a thin layer of gold over the top. Enig Finish PCB provides various advantages such as high strenght, low contact resistance and etc, so it's widely used in many applications.