There are a variety of materials to choose from to support your design performance requirements, starting at the bottom with FR-4, through a wide array of high speed materials between FR-4 and Teflon.

The quality of the materials used significantly impacts the effectiveness and longevity of your PCB. By selecting high-quality materials, you can ensure that your circuit board not only functions correctly but also endures throughout the expected lifespan of your product.

If you choose incorrect materials, your PCB, along with the product it resides in, may not perform as intended. Therefore, the material selection process plays a crucial role in the success of your PCB design and overall product functionality.

In this article, you will find the most common types of materials and key considerations for choosing the right pcb materials.

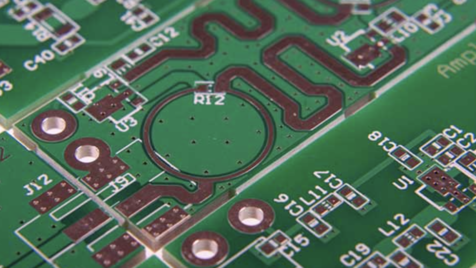

PCB material refers to the base material used to construct the circuit board. It provides the structural foundation and electrical insulation for the circuit components and interconnections.

The choice of material plays a crucial role in determining the electrical, mechanical, and thermal characteristics of the PCB, ultimately impacting its performance and reliability in various electronic applications.

PCBs are typically made of multiple layers of different materials. The primary materials used in the construction of a PCB include:

The substrate, also known as the base material or PCB laminate, forms the foundation of the PCB. The most common substrate material is FR-4 (Flame Retardant 4), which is a fiberglass-reinforced epoxy laminate. FR-4 provides excellent electrical insulation, mechanical strength, and heat resistance. Other substrate materials like FR-2, FR-1, CEM-1, and polyimide (for flexible PCBs) are also used depending on specific design requirements.

Copper foil is used to create the conductive pathways on the PCB. It is typically laminated to the substrate material using heat and adhesive. The copper foil serves as the conductive layer for routing electrical signals and power distribution throughout the PCB.

The solder mask, also known as solder resist, is a protective layer applied over the copper traces and pads on the PCB. It is usually made of epoxy-based materials that are cured to form a durable and electrically insulating coating. The solder mask helps prevent solder bridges, protects against corrosion, and provides visual contrast for easier assembly and inspection.

The silkscreen layer is an additional layer applied on top of the solder mask. It contains printed text, symbols, and markings that provide component references, part numbers, and other useful information for assembly and identification.

In addition to these primary materials, PCBs may also incorporate various additional materials such as vias, solder paste, soldermask openings (known as soldermask windows), and specialized coatings for specific applications or environmental considerations.

FR-4 is a commonly used material in PCB fabrication. It is a flame retardant laminate that meets the standards set by the National Electrical Manufacturers Association (NEMA). FR-4 consists of a layer of woven-glass fabric combined with an epoxy resin binder. It has been in use for over 50 years and has undergone advancements, allowing it to withstand continuous operating temperatures of up to 180°C. However, FR4 doesn’t have the best coefficient of thermal expansion (CTE) and electrical characteristics for high-quality signal speed, which is why the material is being used less frequently in PCB fabrication.

Rogers materials are specialized laminates used for high-frequency applications, particularly in RF and microwave circuits. These materials have low dielectric loss, excellent signal integrity, and controlled impedance properties. Rogers materials are available in various formulations to meet specific frequency and performance requirements.

PCBs still use traditional materials such as copper, aluminum, and iron. These materials allow the integration of components using Surface Mount Technology (SMT). They also provide mechanical durability. Therefore, the product life of metal-based PCBs is much longer.

PTFE-based materials, such as Teflon, are primarily utilized in specialized applications that require exceptional performance in high-frequency and RF/microwave circuits. These applications often demand precise impedance control, low signal loss, and stable electrical properties across a wide range of frequencies. These applications may include aerospace, telecommunications, radar systems, and other advanced RF/microwave technologies.

FR-2 is a phenolic-based paper laminate material. It is commonly used for single-sided and double-sided PCBs. FR-2 has moderate electrical insulation properties and lower mechanical strength compared to FR-4. It is often used in low-cost consumer electronics and general-purpose applications.

Polyimide is a flexible substrate material that can withstand high temperatures. It is often used in flexible PCBs (FPCBs) and rigid-flex PCBs, where the board needs to bend or flex without breaking. Polyimide offers good electrical insulation and thermal stability.

Download this pdf from idc-online.com to see the pcb materials properties.

Material | Typical application |

| RO3000 |

|

| R04000 |

|

Polytetrafluoroethylene (PTFE) |

|

Polyimide |

|

PEEK |

|

Aluminum, or alumina (Al2O3) |

|

Aluminum nitride (AlN) |

|

Beryllium oxide (BeO) |

|

selecting the right PCB material is crucial for the success of your project. Here are some key factors to consider when choosing PCB material:

Design and Purpose of the Circuit Board: Consider the overall design elements and the intended purpose of the PCB. Determine the required signal integrity, environmental conditions, and any specific functionality needs. This will help determine if a flexible or rigid board is necessary and if the board needs to withstand high temperatures.

Heat Transfer, Conductivity, and Power Thresholds: With the high-speed signals today, overheating is a reality in a wide variety of products, especially those that have a built-in cameras such as cell phones and laptops.

Stackup: Determine whether a single-layer or multi-layer stackup is needed based on the design requirements. Consider impedance requirements and how the chosen stackup will fit within the mechanical constraints of the device.

Mechanical Strength: Ensure that the selected materials provide both electrical and mechanical strength. Consider the coefficient of thermal expansion (CTE) of the materials, as it is critical in microelectronics to ensure the PCB functions properly under varying temperatures.

Electrical Signal Integrity: Depending on the function of the board, categorize it as high frequency, high power, high density, or microwave. Select materials that can maintain signal integrity based on the specific board type.

Component Location: Pay attention to the location of components to avoid interference or noise that can degrade signal integrity. Properly position components to minimize signal disruption.

Flexibility: If flexibility is required, consider using a rigid-flex board, which combines flexible and rigid materials. This enables the board to be bent or folded into different shapes. For applications that need thin and flexible circuits, consider using flexible materials.

Cost of Materials: Evaluate the cost implications of materials, especially if the board contains gold, blind or buried vias, or via filling. These features may require additional fabrication processes. Consider that line and width spacing below 6 mils and certain surface finish options can also impact costs.

Choosing the wrong material can seriously delay your PCB project or impact your budget, so it's important to consult an experienced professional right from the start. At VictoryPCB, our skilled engineers work with customers from the very beginning of any project, advising on materials, layup and design for manufacturability.

Our manufacturing capabilities allow us to provide customized PCB solutions, including specialized material selection, stackup design, and impedance control, to meet your exact specifications.

Contact us now at Sales@victorypcb.com to partner with a professional PCB manufacturer who can guide you in selecting the right PCB material for your project. Let us assist you in making an informed decision and providing you with top-quality PCBs that meet your specific needs.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us