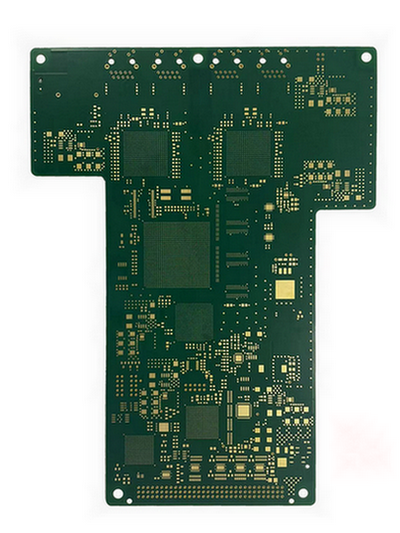

14L High Density HDI Immersion Gold PCB for Telecom Device

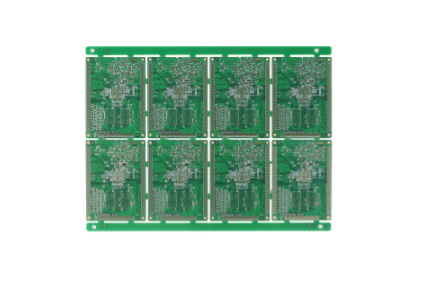

Victory able to provide High Density PCB Prototypes, small and medium-volume High Density PCB.

We not only produce High Density PCB Prototypes, small and medium-volume High Density PCB is also no problem. We can make up to 48 Multilayer PCB, Min. Hole Size 4mil, Min. line width/space 3mil.

Find out about our more info, Please contact us at sales@victorypcb.com.

Monthy Capability: 3900 Sq M/Month

Layer: 14 Layers

Material: FR4 TG180

Finished board thickness: 2.0mm

Outer layer Finished copper thickness: 1.5oz

Inner layer base copper thickness: 1oz

Min Trace Width/Space: 3/3mil

Min hole size: 0.2mm

Min hole wall copper: ≥25UM

Soldermask Color: Gloss Green

Silkscreen Color: White

Surface finishing: Immersion Gold

Application field: Industrial control