Printed circuit boards have become central in the manufacturing of numerous electronic devices. PCB manufacturing cost depends on many factors, such as design complexity and product performance. Knowing these factors ahead of time will allow you to budget accordingly, work with the right supplier, and put your business in the best position for success.

At VictoryPCB, we have a convenient online PCB cost calculator that can help you manage your pricing! Some of the most important factors that will influence the cost of your PCBs include:

Generally, the more layers a PCB has, the more expensive it will be to fabricate. This is because adding layers to a PCB increases the complexity of the manufacturing process, which in turn increases the cost.

A single-layer PCB, also known as a single-sided PCB, is the most basic type of PCB. It consists of a single layer of conductive material, typically copper, on one side of an insulating substrate, such as fiberglass or plastic. These are the cheapest PCB to fabricate and widely used in simple electronic circuits.

A double-layer PCB, also known as a double-sided PCB, is very similar to single sided PCBs, except that they have two sided traces with a top and bottom layer. These boards can mount conductive copper and components on both sides of the circuit board, which allows the traces to cross over each other. They are widely used in consumer electronic devices and appliances.

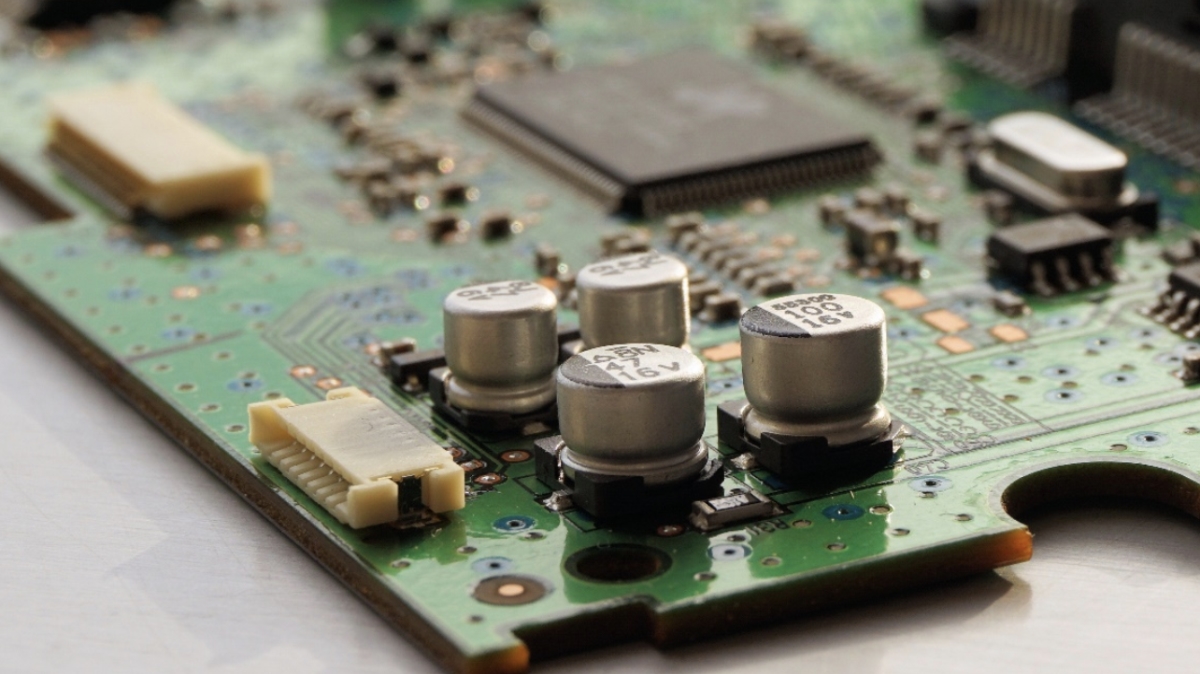

Multilayer PCB is a printed circuit board with more than two layers and has a minimum of three conductive layers of conductive material or copper layer. When looking at a multilayer PCB, the top and bottom layers look similar to a double-sided PCB but they have more layers on both sides of the core. Multi-layer PCBs are widely used in high-end electronic devices and critical applications such as aerospace, medical, and military.

PCB thickness can affect the overall physical size of the device, as well as the weight, flexibility, and thermal dissipation. Here are some of the most common thicknesses of PCBs:

1.6mm: This is a standard thickness for single-sided and double-sided PCBs, it provides a balance between mechanical strength, thermal dissipation, and cost.

1.2mm: This thickness is commonly used for double-sided and multi-layer PCBs, it allows for a smaller form factor and lightweight designs, but also demands more precision in the manufacturing process.

0.8mm: This thickness is used in high-density designs, such as in high-end smartphones, laptops, and other portable devices where space is limited and weight is a concern.

0.6mm: This thickness is used in applications where size and weight are critical, such as in small medical devices, wearable technology and compact electronic devices.

2.0mm and above: These thicknesses are more common in industrial and military applications, where the PCB is exposed to harsh environments, and a high mechanical strength is needed.

PCBs are made out of different materials like fiberglass, polymer inks, and solder. The conductive layers are usually made of copper, gold, or silver. These materials can affect the way the board reacts to heat. PCBs need to have thermal reliability and temperature reliability. They also need to have other mechanical properties that affect the performance of the board and the device it powers. When PCBs need to have higher frequencies, the boards need to be made of higher-grade materials – like gold or silver – than the standard copper boards. Some materials are more expensive than others. For example, gold and silver might be needed to make your PCBs, but they are also more expensive than copper.

Some manufacturers are building PCBs with a quick, turn-key turn around time. When manufacturers are asked to produce PCBs quickly, they will charge more money. Often, manufacturers have to put other orders on hold to get a quick turnaround on another order. The increased price will cover the expense of putting other orders on hold.

If you are looking for a way to reduce your costs, place your order early. This gives your manufacturer time to complete the order without forcing them to pay overtime or higher shipping costs to get parts.

Even though it is true that you will have to pay more money if you want to order more PCBs, it is also true that you might be able to reduce your overall cost if you order them in bulk. Once a prototype is made, it is easy to duplicate them. Building the prototype is expensive, which is why small orders cost more per piece than a bulk order does. Many companies will discount bulk orders, so do not be afraid to request a lower price.

The technology that manufacturers use to produce the PCBs will also affect the price. Manufacturers use one or two different production methods to make PCBs: surface-mount technology or through-hole technology. Surface-mount technology is the least expensive of the two because it uses more automation, which requires less manpower and lower employee costs.

Once your order is finished, the manufacturing team has to get it to you. You will have to cover the cost of shipping one way or another, and there are a number of factors that will play a role in how expensive it will be to ship your PCBs. They include:

The total distance the order has to travel to make it to you

How quickly you want to receive the order

The packaging materials used to protect your order as it travels to the final destination

PCB costs are often determined by custom specifications. If you are looking to save money on PCB manufacturing, it is best to design a board that has few customizations. Try to use component designs from previous boards.

At VictoryPCB, we do not do any design work, but we can help you if you have a design that has already been created. We can work with you to customize your PCB to meet your needs.

The factors above are just a few of the many factors that will influence the cost of your order. But before you choose a PCB manufacturer, it is important to consider other factors outside of cost. These may include:

Quality and reliability: A good PCB manufacturer should have a proven track record of producing high-quality, reliable boards. We are certified to ISO 9001:2015, ISO 14001:2015, IATF 16949:2016, ISO13485, SA8000 IECQ QC 080000:2017 and UL certification.

Manufacturing capabilities: The manufacturer should have the necessary equipment, experience and skills to produce your PCB design. Check out our manufacturing capabilities.

Lead time and delivery: PCB manufacturing can be a time-consuming process, and you’ll want to make sure the manufacturer can deliver your boards within your required timeframe.

Post-sales services:

Some manufacturers offer additional services such as testing and assembly, also consider if any warranties or guarantees are offered after the delivery.

The cost of manufacturing PCBs is affected by several factors. It is important that you choose a company that meets your technology needs and also meets your budget. If you are looking for a company that has the expertise necessary to produce your printed circuit boards within your budget, please contact us today.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us