PCBA testing mainly includes five forms: ICT testing, FCT testing, Burn In Test, Fatigue Test, and Severe Conditions Test:

The ICT (In-Circuit Test) test mainly includes circuit continuity, voltage and current values, fluctuation curves, amplitude, noise, etc., and does not involve function keys or input and output tests.Some like AOI test,X-ray test.

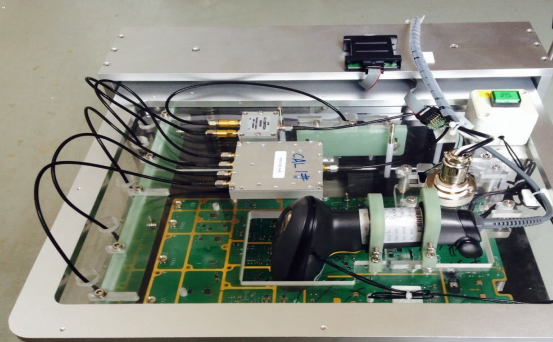

For FCT (Functional Test) testing, you need to first burn the prepared microcontroller (MCU) program into the program IC through a burner (such as ST-Link, JTAG) to simulate the function of the entire PCBA board, such as after pressing a button , The LED light is on; press the two buttons at the same time to restore the factory settings and so on. So as to find out the problems in the hardware and software, and equip with necessary patch processing production jigs and test racks.

Burn In Test is mainly to perform long-term and periodic simulation of user input and output on PCBA boards that have been programmed and FCT passed to test their durability and welding reliability. Only after the aging test can electronic products be sold in batches.

Fatigue Test is mainly to sample PCBA boards and perform high-frequency and long-term operation of functions to observe whether failures occur and determine the probability of failure in the test, so as to feed back the working performance of PCBA boards in electronic products.

Severe Conditions Test mainly exposes the PCBA board to extreme temperature, humidity, drop, splashing, and vibration, and obtains the test results of random samples, thereby inferring the reliability of the entire PCBA board batch product.

Victory is a professional PCB manufacturer which established in 2005. Adhere to be a specialized manufacturer for multiply species, small to medium series, and quick turn production, we insist to provide 3H(high quality, high precision and high density) PCBs for our customers.

With a total plant area 30,000sq.m, our monthly capability can be 60,000sq.m with 3000 parts. Our factories located in the modern Industrial Park of Shenzhen City. With advanced PCB production and testing equipments, and well-found quality system to monitor throughout the whole manufacturing to assembly, we can ensure the stable and excellent quality of the production process to meet customers' requirements. If you have any inquiry, please contact us immediately.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us