These are a popular type of metal core printed boards (MCPCBs) popular in modern application use. Due to its copper-clad laminates and metal-based components, it makes a great conductor and also an excellent insulator.

The circuit board feature helps in efficient heat dissipation, and this is usually a function of the support offered by the thermal clad layer.

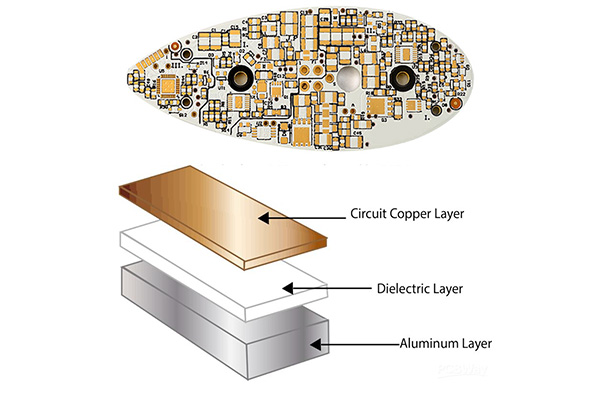

Components of aluminum PCB

There are different layers found in the boards. This is as a result of the board's different design and manufacturing process in comparison to other types of PCBs. The PCB is made of three main layers.

• Thermal insulation layer

The insulation layers are made of ceramic polymer. A polymer has good thermal resistivity and viscoelastic characteristics as well.

This layer is the most important as it helps protect the circuit board from any form of mechanical and thermal stress.

• Circuit layer

The insulation layer of the circuit board consists of components of copper foil. These foils can be used in varying weights ranging from 1-10 ounces.

• Base layer

This layer is composed of aluminum alloy substrate. Due to the presence of aluminum in them, these types of PCBS are a great match for through-hole technology.

Types of aluminum PCB

1. Flexible PCBs

In these types of PCBs, the major feature which provides it with its high level of flexibility, thermal conductivity as well as electrical insulation is the presence of flexible PCBs dielectric parts.

2. Through-hole PCBs

In this type of aluminum circuit board, the aluminum is pre-drilled. After drilling, the dielectric is back-filled into the hole.

3. Hybrid Aluminum PCBs

These types are generally used in RF applications. they are famous for their better thermal performance ability.

Advantages of aluminum PCB

• They are less expensive

Aluminum in comparison to other metals such as copper,steel and brass is relatively cheaper.

Due to its availability in almost all climatic conditions means easy refining in comparison to the above mentioned substitutes, which in turns leads to lesser cost of manufacturing and purchase. This makes it an economical option over any other substitutes.

• Durability

Aluminum is known for its strong and durable nature. Its sturdy nature helps minimize the chances of accidental breakages and damages that may occur in the process of daily use or manufacturing process.

• Environmental friendly

Aluminum is not only recyclable but is also no threat to the environment. This makes it eco-friendly and safe to use.

• High heat transfer

Upon exposure to high temperatures, most components get damaged. this is not the case with aluminum. it has the capacity of carrying heat away from critical parts. hence preventing damages to these parts.

• Heat radiation

Aluminum PCB are notoriously known for their rugged heat radiation and consist of a better strength.

• Light-weight

This may be said to be its biggest advantage. The light-weight characteristics of aluminum makes it sturdy and resilient. The following advantages of aluminum PCBs, makes it one of the most widely used and common circuit boards in the world.

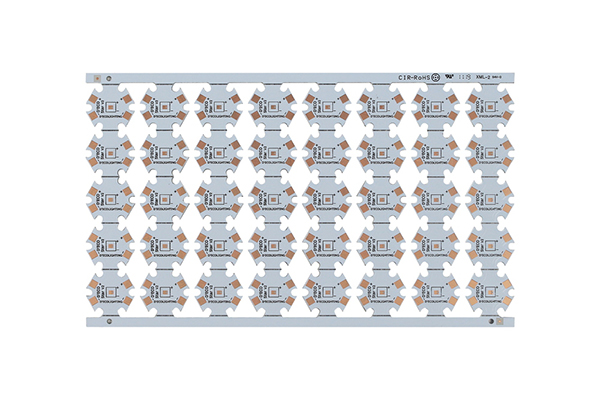

They are used in applications that require high heat dissipation or high power. They are commonly used in LED applications such as general lighting, display signs and even traffic lights.

It is also used in surgical lighting equipment, tail light assemblies, signal beacons and also used in automotive dashboards and many more appliances.

Why you should choose us for your quality aluminum PCB

Are you in search of a reliable and reputable manufacturer of aluminum PCB? Do you need a company to meet up with all your PCB needs? need a variety of PCB? Click here, to get everything you need at your disposal.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us