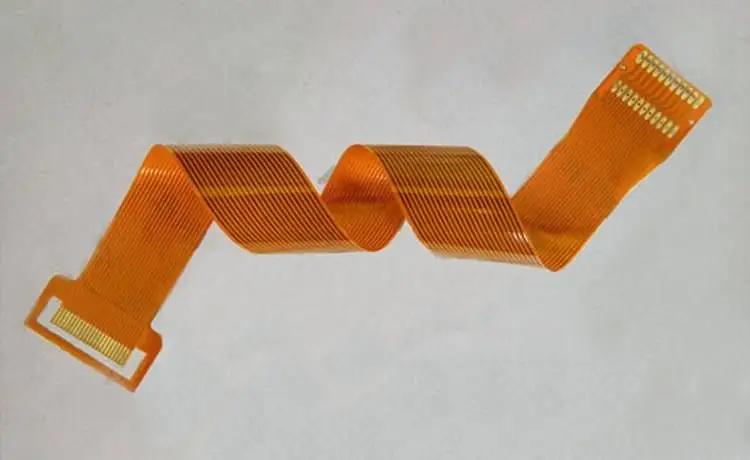

As the name implies, the flexible printed circuit board is a flexible material derived from polyimide. There are many types of circuit boards used to serve different purposes.

These are single-sided, double-sided, yellow, black, white, and transparent. You can use this material in automobiles, clothing, and many other industries.

In addition, you carry this material around without realizing it because Flexible printed circuit boards can be found in many modern industrial products such as smartphones, laptops, calculators, cameras, and other modern electronic gadgets.

Step 1

This first step is the most important in making PCBs. It involves washing the glue or paste off the copper foil. This is done by dipping the copper foil into acid to rid it of any form of the adhesive coating.

The coating needs to be removed because it presents a dilemma in the process of manufacturing flexible print circuit boards.

Step 2

The second step comes after cleaning the laminate. This involves two significant processes to achieve; Screen printing and Photo images.

This is done by placing the circuit image in the middle of the copper laminate and the UV light. This will reflect in the circuit image on the surface of the laminate.

Step 3

This step involves the etching process. The etching process is very tedious. It involves spraying the copper laminate in NaOH solution which will achieve the desired result of preserving the circuit image and removing unwanted copper materials. The etching process sets the stage for the drilling process.

Step 4

The next step involves drilling some small holes, pads, and vias to prevent or repair damages due to electrical tests. In this stage, High-speed drilling tools and laser drilling techniques are employed in determining the precision, size, and shapes of holes made in the copper layer.

Step 5

The plating process involves drilling accurate holes to allow electrical current to flow seamlessly through the copper materials of the flexible print circuit boards. In addition, this is done to allow interconnectedness between layers.

Step 6

Manufacturers use polyimide film as a cover coat to protect the flexible print circuit board from harsh weather conditions, dangerous chemicals, and solvents. Cover lays are usually meshed on the surface of the copper laminate, and then laminated using high temperature or heat.

Step 7

When making flexible print circuit boards, manufacturers cut the flex in the production processes to avoid any damage to the flexible print circuit board.

In situations where the products produced are large in quantity, it is advisable to use the hydraulic punching method to save costs. Otherwise, a blanking knife should be used to cut the flex.

Step 8

Another step taken when making a flexible circuit board is electrical testing. This is usually done to maintain a high standard of quality products.

If peradventure there is a problem or flaw in the design boards, it is expected that it will affect the product's functionality and productivity. This is why it is important to validate the circuit boards through consistent testing and examination.

Flexible print circuit boards are pliable and durable, making them an essential component in many electronics.

Due to these reasons, you can use flexible PCBs in automobiles, airplanes, computers, and smartphones. You can also use them to power medical equipment like glass hearing devices, cameras, gastroscopes, etc.

· They reduce the number of wires needed for connections

· They are resistant to high temperatures or heat

· They are flexible and resilient

With over 17 years in the business of manufacturing and delivering high-quality flexible PCB, we have earned the trust of our customers worldwide as the only reliable manufacturer and the source of the best PCBs.

So, in case you find yourself at the crossroad about which brand of Flex PCBs to patronize, you can always bank on us to deliver the best possible deal at a price that won’t break the bank.

Kindly click here to reach us for purchase or to make inquiries about our products and services.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us